In computers, many parts can produce a lot of heat and need cooling.

The CPU and GPU are the primary two sources of heat.

They generally both need active cooling, even in a case with good airflow.

RAM, SSDs, VRAM, VRMs, and the chipset produce a fair amount of heat.

The process is pretty fundamental physics.

However, it requires good contact to transfer the heat efficiently.

Bringing the heat sink to have good air contact is more straightforward than trivial.

As a gas, the air neat conforms to the shape of the heat sink.

The only consideration is maximizing the surface area of the heat sink.

However, getting good contact between the actual heat-producing part and the heat sink is more complicated.

The flattening process can leave microscopic grooves, letting some air get in that actually insulates the heat transfer.

To minimize these issues, a thermal compound is generally used.

These typically come in four formats with different use cases, advantages, and disadvantages.

Contents

Thermal Paste

Thermal paste is the most commonly thought bang out of thermal compound.

It can also be referred to as thermal grease and TIM, short for Thermal Interface Material.

Exact mixtures vary, but its generally a polymer paste with tiny metallic particles.

The intent is that a small amount is placed on the surface to be cooled.

Some, however, come in sachets that can be more difficult to apply and are generally quite messy.

Thermal conductivity is measured in W/mK, or Watts per meter Kelvin.

Higher numbers are better as more heat can be transferred.

Thermal pastes typically offer around 8W/mK.

It cant cause a short.

Thermal paste is typically used between CPUs and their coolers and GPUs and their coolers.

Thermal paste generally dries out over time and will often show degraded performance after around two years.

At this point, it should be cleaned off and reapplied.

Typically, thermal paste doesnt feature any adhesive capabilities.

Thermal Pads

Thermal pads are basically tiny thin sponges that conduct heat well.

The pad tends to be slightly adhesive, making removal difficult, especially if the pad breaks apart.

Thermal pads offer a layer of protection for pressure-sensitive components.

Mounting pressure can sometimes cause components to crack, especially if not all the components are perfectly level.

The small sponge of a thermal pad allows it to absorb that pressure and helps to level components.

Thermal pads are typically not used to cool CPUs or GPUs.

However, they often feature on VRAM, VRMs, RAM, and SSDs.

These devices generally dont output as much heat.

So the reduced thermal conductivity compared to paste isnt an issue.

The cost savings are, however, appreciated.

Solder TIM

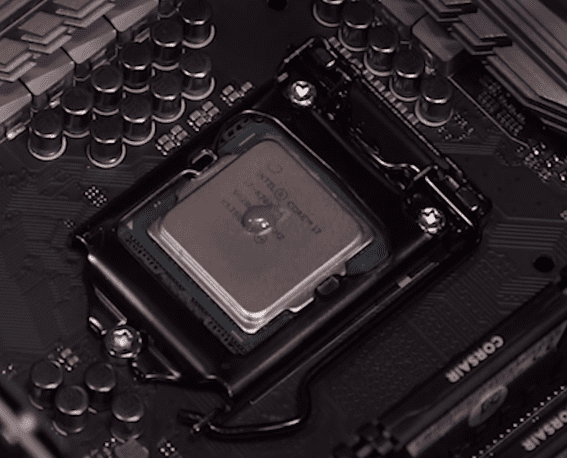

A CPU actually has two layers of the heat sink.

The CPU die is covered by an Integrated Heat Spreader or IHS.

The IHS is then cooled by the heat sink with a standard thermal paste layer between them.

In some scenarios, standard thermal paste is used.

However, the surface area is small, making heat transfer harder.

In modern processors, solder transfers heat between the CPU die and the IHS.

As a metal, the thermal conductivity of solder is much higher, at around 50W/mK.

It is also electrically conductive, so care must be taken to insulate nearby components.

Liquid Metal

Some enthusiasts and extreme overclockers opt to use a liquid metal thermal compound.

These are based on gallium, a metal liquid at room temperature.

However, it is generally alloyed with other metals.

This means it can be applied similarly to the standard thermal paste.

It offers excellent thermal conductivity, on the order of 60W/mK.

Using it can see multiple degrees of temperature drop as heat is more efficiently transferred away.

As much as that sounds great, there are several difficulties.

Great care must be taken when using liquid metals.

First of all, gallium shouldnt be directly handled.

Liquid metal is much less dense than thermal paste, so much less needs to be used.

Its electrically conductive, so it can cause short circuits if it spills out onto components.

Gallium is also spectacularly corrosive to aluminum, which is incompatible with aluminum-based heat sinks.

Liquid metals are tough to clean off if you want to reapply them.

Conclusion

Thermal compound refers to any form of thermal interface material.

Other types are available, though, with different advantages and disadvantages.

Performance is measured in thermal conductivity with the units W/mK.