A standard CPU has three core parts.

These are the substrate, the CPU die, and the IHS.

The substrate is the PCB on which the rest of the CPU is placed.

It has the CPU socket connector pins on its underside.

The CPU die is the actual CPU.

Its precisely etched silicon that performs the processing.

The CPU die also features the CPU cache tiers directly integrated to minimise communication times.

The IHS is the Integrated Heat Spreader.

It presses directly onto the CPU die and transmits the heat it produces to the CPU cooler.

The IHS also offers protection against die cracking.

The CPU die is fairly brittle, and the mounting pressure of the CPU cooler could crack it.

The IHS neutralises this risk as it doesnt transmit that pressure to the CPU die.

Unfortunately, this doesnt work quite as well when there are multiple dies on a single CPU.

For example, this would also apply if the CPU featured an FPGA or memory directly on the package.

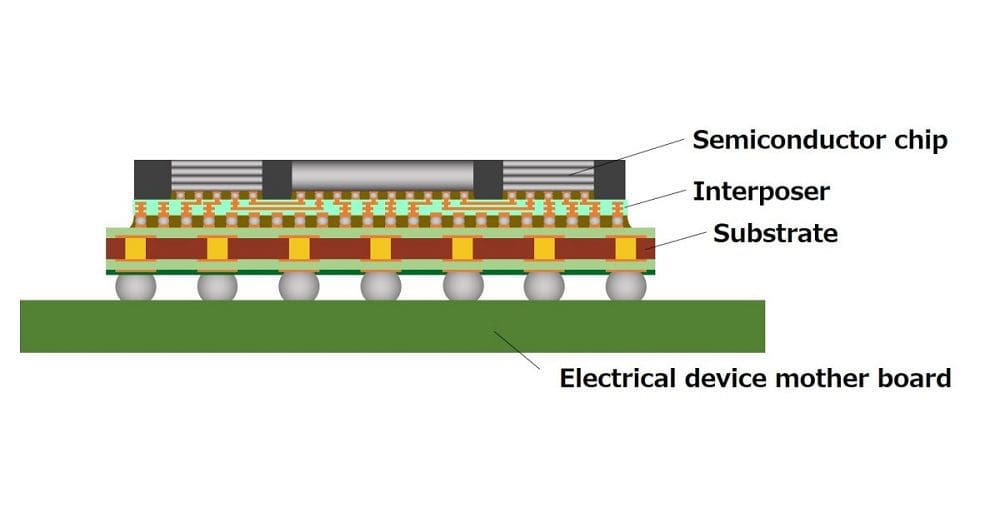

This CPU die in blue, can be seen on a brown interposer that covers almost the entire substrate.

An interposer is simply an intermediary layer between the package substrate and the CPU die.

The interposer then uses TSVs or Through Silicon Vias to pass the electrical signals through with no degradation.

The silicon interposer also allows for die-to-die communication connectivity.

Firstly, the silicon interposer has a much lower coefficient of thermal expansion.

This means that smaller solder bumps can be used as the silicon can handle the increased thermal load.

The second benefit is that silicon interposers can have much narrower traces etched into them than the substrate can.

Allowing for denser more complex circuitry.

If a company already has this hardware lying unused, it can be reused for this purpose.

Conclusion

An interposer is an intermediary between the package substrate and the CPU die.

Its typically made of silicon.

It offers good thermal stability for small-scale, high-density connections.

This feature is particularly useful for chiplet-based CPUs.