One of the common methods of post-processing prints made with ABS is called Acetone Smoothing.

Acetone smoothing is smoothing and eliminating layer lines by placing the print in an acetone mist.

Nicely, doing so also leaves the print with a smooth and shiny surface.

Image courtesy of engineerdog.com

Of course, things can go wrong.

If you dont leave the print in long enough, the layer lines will still be visible.

Obviously, dissolving some of the material in a 3D print is going to change it somewhat.

Especially for functional prints, one of the most important features that changes are the prints strength.

The most extreme example would be a long stick.

When printed vertically with a lot of small layers, it is straightforward to snap.

Does Acetone Smoothing Affect the Strength of ABS?

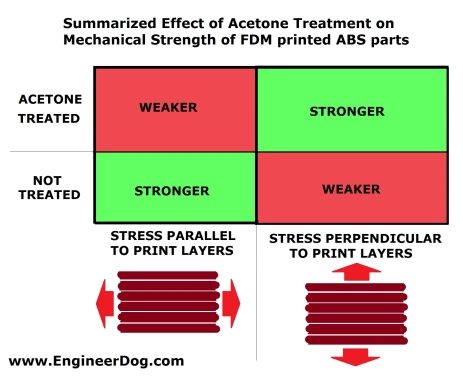

Its a common misconception that acetone smoothing outright increases the strength of ABS prints.

However, that isnt the entire story.

Practical research does actually confirm this to be the case.

Research performed byMichael Grahamshows that acetone smoothing does indeed strengthen ABS parts by 31%.

Theres a caveat though, this strength increase only applies perpendicular to the layer lines.

Acetone-treated ABS prints are actually 9% weaker to forces parallel to the layer lines.

Image courtesy of engineerdog.com

Acetone smoothing does indeed strengthen layer bonds by reducing stress points.

This knowledge can, however, help you take advantage of the directional strength increase.